-

Featured News

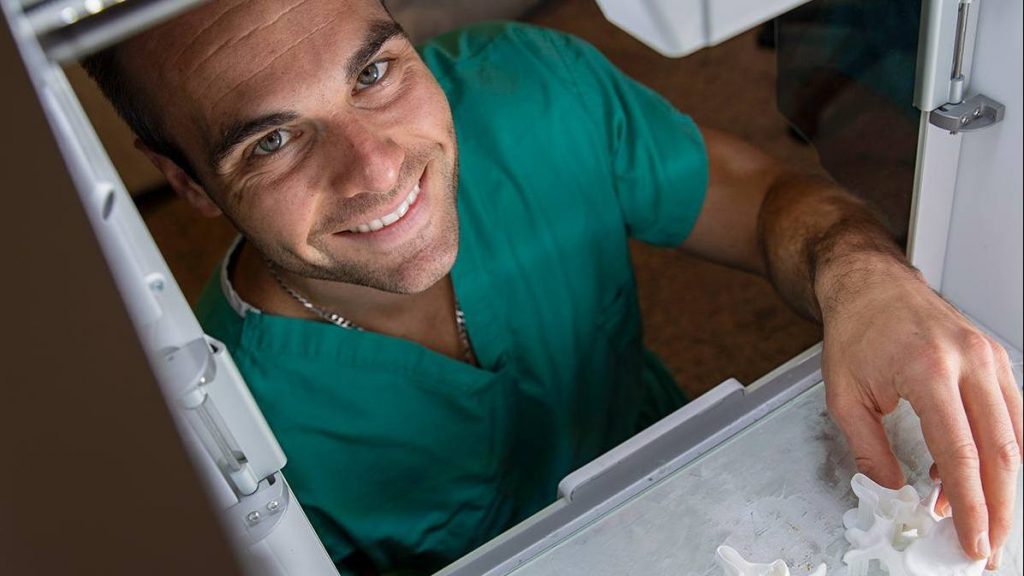

Helping Others Heal: Neurosurgeon invests in 3D printer to improve surgery results

Blueprints take shape through ingenuity and time at the drafting table. At Mayo Clinic, new draft designs can guide physician-scientists toward milestones in the field of medicine.

William E. Clifton, M.D., had an idea to tap into the realm of 3D printing for medicine. As one of the first recipients of the Mayo Clinic John H. and Carolyn O. Sonnentag Neurosurgery Residency in Florida, Dr. Clifton believed he could find new ways to train surgeons by creating 3D-printed models.

Many ideas, including Dr. Clifton’s, are well thought out and worthy of funding, but Mayo Clinic’s pool of resources is finite and space is limited.

So he rolled out his own blueprint to bring his design to life. Dr. Clifton purchased a 3D printer with a personal loan and safely stashed it in the corner of a bedroom in his home. Similar to the difficulty of securing research space at work, space is a commodity at home with his wife, Kristen, and their four children.

“When the 50-pound box was delivered, my wife and I shared a big smile. Of course, she added a more appropriate eye roll. Then Kristen took the lead, and we set it up in the bedroom.”

Dr. Clifton worked in his free time using the 3D printer to practice his innovative idea. It was these early designs that helped him build the training models used today.

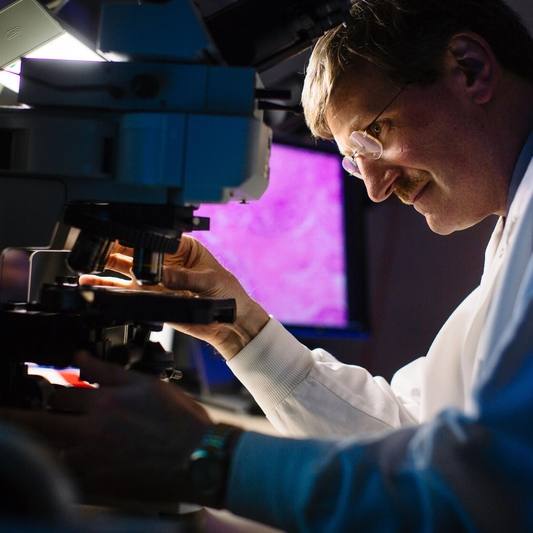

Visualize the Architecture

Early in his journey, Dr. Clifton sought the advice of his faculty mentor in spine surgery, Mark A. Pichelmann, M.D., who recognized the importance of this work and encouraged Dr. Clifton to meet obstacles head-on.

“At Mayo Clinic, many clinicians are heavily engaged in groundbreaking research,” Dr. Pichelmann says. “It’s important for physician-scientists to balance time between seeing patients and building our knowledge base — for the betterment of patients and the advancement of the field. We continue to strive to be at the forefront of patient care, research and education.”

Fast-forward eight months to more than 20 peer-reviewed publications penned by Dr. Clifton, as well as several patent submissions for neurosurgical devices. The Department of Neurologic Surgery also is heavily engaged in planning for dedicated neurosurgery 3D printing space and a materials science laboratory based on the ideas and infrastructure Dr. Clifton helped create.

“One of the distinct advantages of 3D printing is that it allows us to build models made from different material compositions and properties. We do this to simulate different disease processes for resident training, and to approach patient care and surgical planning in an individualized way,” Dr. Clifton says.

Read the rest of the story in Mayo Magazine.