-

Research

Science Saturday: Biomanufacturing 101 — Understanding a new era of therapeutics

Advancing cellular discoveries from clinical trials to commercial therapy is a cornerstone of Mayo Clinic's strategic emphasis on biomanufacturing. The long-term vision is to provide new cures for patients with unmet needs.

"Biomanufacturing is a type of manufacturing that utilizes sources from the human body — cells, blood, enzymes, tissues, genes or genetically engineered cells for use in medicines. We call these biologics," says Julie Allickson, Ph.D., the Michael S. and Mary Sue Shannon Family Director of Mayo Clinic's Center for Regenerative Medicine. "Biologics become a living drug within the body aimed at continually healing damaged tissues and cells." Dr. Allickson is also the Otto Bremer Trust Director, Biomanufacturing and Product Development, Center for Regenerative Medicine.

Biomanufacturing next-generation drugs

Biomanufacturing could usher in a new era of biologically based medicines that show hope of going beyond available complex molecule-based drugs to treat illness.

These next-generation biotherapeutics derived from living organisms show potential to:

- Target specific cells or tissues needing repair.

- Trigger fewer adverse effects.

- Personalize therapies for conditions that previously had no known treatments.

- Enable large-scale manufacturing in a cost-effective manner.

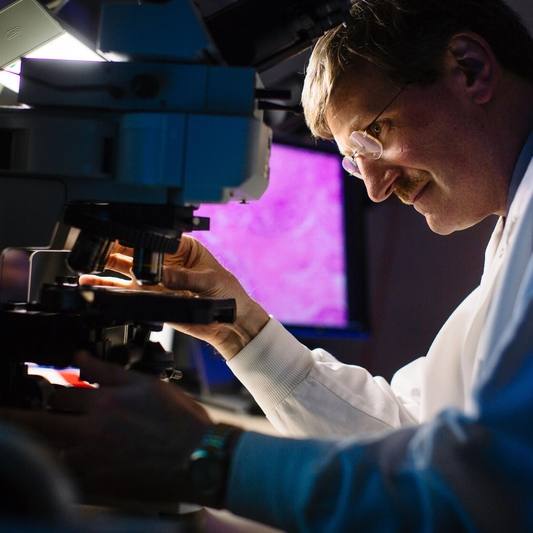

The Center for Regenerative Medicine is seeking to create the world's most advanced ecosystem for biomanufacturing new biotherapeutics, bringing together physicians, scientists, process development experts, high-tech facilities and industry collaborators to test and license first-of-their-kind biologics. The center will collaborate with the Mayo Clinic Comprehensive Cancer Center, the Center for Individualized Medicine, the Department of Laboratory Medicine and Pathology, Mayo Clinic Ventures, Mayo Clinic Platform, the Center for Digital Health and Mayo Clinic International to execute the biomanufacturing strategy across the institution.

Mayo Clinic has identified seven workstreams for biomanufacturing, but will initially prioritize:

- Induced pluripotent stem cells, which are adult stem cells that can be manufactured to become any type of cell in the body. Master cell banks and new cell lines offer researchers a way to track disease progression and test new therapies in the lab.

- Enhanced immunotherapies such as chimeric antigen receptor-T cell therapy (CAR-T cell therapy) capable of harnessing the body's natural healing ability and expanding treatment from blood to solid tumors.

- Gene editing for disorders with single cell genetic mutations that could provide healing for conditions such as sickle cell disease.

- Bioprinting tissues and organs, which could help avoid the need for transplant and address the shortage of donor organs.

Additional focus will be placed on:

- Extracellular vesicles that can act as drug, protein or gene transporters, delivering healing messages to cells.

- Cellular therapies for nonmalignant clinical indications.

Working with outside collaborators

Mayo Clinic is making significant investments in good manufacturing practices facilities in Arizona, Florida and Minnesota, which are facilities that meet strict quality control regulations required for commercial grade biotherapeutics. This strongly positions Mayo to work with a growing number of industry collaborators interested in bringing to market regenerative biotherapeutics for conditions that previously had no treatment options.

"Our emphasis will be on phase 1 and phase 2 clinical trials for technology developed at Mayo Clinic. Possibly at that time, we might work with industry collaborators that either want to license the technology or launch a startup company," says Dr. Allickson.

Health care costs for chronic and complex diseases run in the billions of dollars every year. Mayo's goal in developing expertise in new biologic-based medicines is to bring the cost of care down while providing new hope for patients.

###

Related Articles