-

Featured News

#ThrowbackThursday 1981: Paint shop touches all of Clinic

The finishing touch is usually the last part of a job and a time to celebrate the completion of a project. But for the Clinic’s Paint Shop, a finishing touch is business as usual.

Everything from furniture to parking lot signs comes under the painter’s skilled brushes and spray guns. “Anything other departments want finished or refinished ends up here,” Dennis Sandvik, the shop’s supervisor, said.

The paint shop is located on the fifth floor of the Franklin Heating Station. In addition to a large, bright work room, the shop has two ventilated spray booths, a drying room and a storage area. One of the two booths is located on the building’s fourth floor. The shop is kept neat and spotless.

“This is one of the last areas in the Clinic not to be air conditioned,” Sandvik said, explaining that ventilation of the spray booth requires free air circulation.

A great deal of the shop’s work involves finishing equipment either built or modified by the Section of Engineering. Some glass cutting is also done in the shop for windows, doors and frames.

Sandvik pointed out several control panel covers, white paint still wet, bound for the new surgical suites in the Mary Brigh Building at Saint Marys Hospital. The Section of Engineering built the panels which were sent to the shop for painting.

The three painters in the shop include Carl Odman, Andy Andrist and David Kirkeeng. The three men have a combined service record of 32 years in the shop.

One area that poses the most challenge to the shop is the selection of specialty finishes for equipment. Sandvik said one special device used in x-ray had to be coated with lead foil and covered with Teflon after regular lead point would not shield the radiation.

Equipment used in laboratories and exposed to various chemical agents requires special finishes. “It’s a challenge for us to determine what the best finish is,” he said.

The shop also coats surgical instruments with varnish for insulation.

Two of the shop’s painters are assigned to go out into the Clinic campus to do touch-up and maintenance work. Large painting jobs are handled by contractors. Sandvik also supervises the contract painters working at the Clinic.

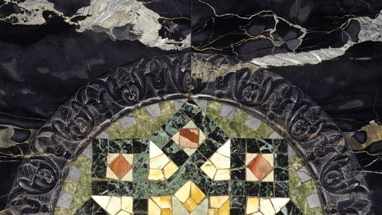

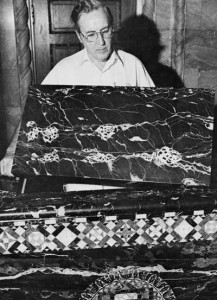

One painter in the shop, Andrist, has developed a special skill for finishing wood to look like marble. Wood panels in several Clinic buildings have been marbleized by Andrist’s skilled brush. The resulting finish is hard to distinguish from the original marble.

Another major job for the shop is updating and repairing signs throughout the Clinic. Any changes in information or prices shown on the painted signs are made by painters in the shop. A stencil cutter is used to make stencils for marking Clinic property.

The shop is busy all the time with various projects. “There is so much of everything to do. It makes the days go by fast,” Kirkeeng said. The shop uses about 300 gallons of paint and finishes annually, Sandvik estimates.

This article first appeared June 1981 in the publication Mayovox.

Related Articles