-

#ThrowbackThursday: Silver Mine Is Time-and-Money Saver for X-ray

This article first appeared December 1953 in the publication Mayovox.

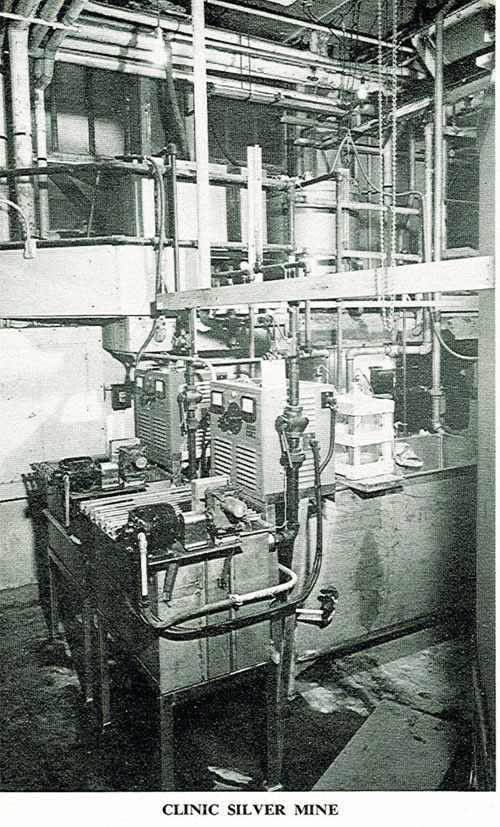

Did you know that the Clinic has a silver mine in the basement? It is located just around the corner from the Stockroom, in the old Engine Room. A maze of pipes and tanks and controls, it bears little resemblance to a conventional silver mine. The fact is, however, that this is one of the most efficient “mines” anywhere, producing silver that is 90 to 95 percent pure.

The “mother lode” of this silver mine is up on the third floor of the 1928 Building, in X-ray’s Dark Room. Here is how it all works, explains Ray K. Runge, in charge of this operation for the Section of Diagnostic Roentgenology.

As you know, x-rays are indispensable tools for medical diagnosis. With such other diagnostic tools as laboratory tests, x-ray examinations provide Clinic physicians with information needed to diagnose patients’ illnesses. X-rays, to be of greatest value for this purpose, must be (a) of top quality, and (b) available for physicians as quickly as possible.

Background for Silver Mine

The continuing search for quality plus speed in x-ray processing is the background for the silver mine in the basement of the Clinic, Runge explains. Just a few years ago, an x-ray film required 86 minutes from the time it entered the Dark Room until, processed and dried, it was ready for use. In 1947, when the bulk of the present x–ray system was introduced, refrigerated dry air and mechanical handling of the films cut the time needed for processing x-rays to 73 minutes.

In the years since, the men in Diagnostic Roentgenology have continued with studies to reduce still further the time needed to get a top quality x-ray film into the physician’s hands. The announcement of plans for the New Mayo Clinic Building, with its expanded x-ray facilities, increased the importance of these studies.

(As simply as a complex process can be explained, here’s how x-ray works. X-ray film consists of a silver halide emulsion coated on both sides of a cellulose acetate base. When hit by x-rays, part of the crystals separates into silver and bromide ions. The crystals so hit contain the latent image which, when developed by chemicals, make the “readable” x-ray film. The crystals not hit by x-rays are removed in another solution known as the “fixer”. These silver crystals not so hit are just that----tiny fragments of silver.)

Highly respected commercial suppliers of film and film machinery were consulted. These companies, working closely with the men in Diagnostic Roentgenology, set a goal: to reduce the 73 minute processing time to just 40 minutes.

Time–saving Possible

It was determined that no time could be saved in the developing tank, without sacrificing quality of the x-ray film. But time might be saved in the drying process, if a new and improved method of film drying could be developed. And further time might be saved in the “fixing” process.

One big problem, then, was to find a way to keep the “hypo” (the common name for chemicals used in the fixing process) at its highest efficiency at all times. This, in turn, demanded a new method for continually clearing the tiny silver fragments from the hypo, rather than, as had formerly been the case, continually facing the problem of emptying tanks of “saturated” chemicals and mixing new batches.

‘Mine’ was Answer

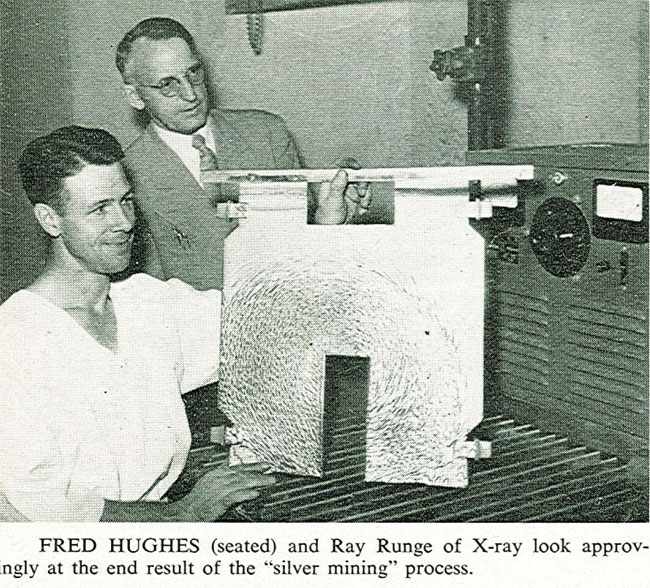

The best answer to the problem was the “silver mine.” Silver recovery cells (see the accompanying illustrations) were installed. A system of pipes was installed between the Dark Room on the third floor and the basement. These pipes carry silverloaded chemicals from the Dark Room to the recovery plant, then take the purified chemicals back for further use in the Dark Room.

The silver recovery process works much the same as that used in electroplating silverware. That is, through electrolysis the silver in the chemicals is “plated” onto sheets of stainless steel. Almost pure silver, it is readily scraped from these plates. It is, of course, highly valuable and saleable.

Proves Itself

The clinic silver mine was installed in the old building to iron out possible “bugs” in the process. It has already proved itself, will be moved to the New Building when Diagnostic Roentgenology moves.

Runge emphasized: “Processing the film faster was the primary consideration in putting this new device into operation. The silver recovered and sold, the saving on re-use of chemicals, is a valuable, interesting –but secondary-consideration.